Get it done today!

Experience the difference experience can make. Whether it’s cleaning, inspecting, moving, or reusing material. We get it done.

Let's do itConfused? It happens to the best of us. Take a look as some common questions and answers outlined below. If you’re still perplexed give us a call. We’d be happy to help.

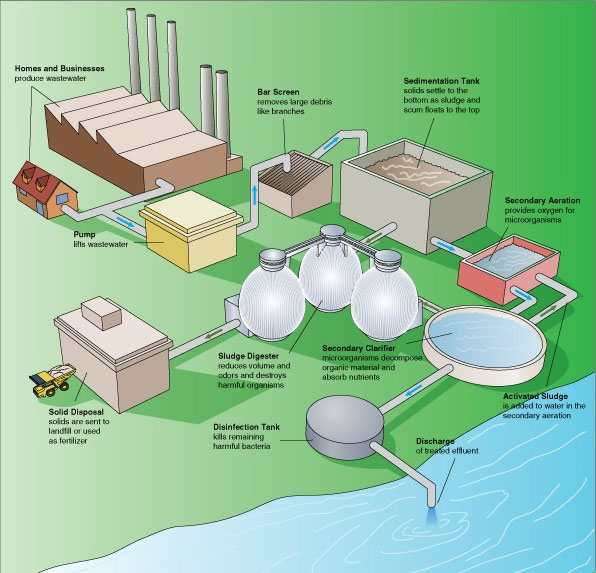

Biosolids are nutrient-rich, processed organic material derived from wastewater treatment. They contain nitrogen, phosphorous, organic matter and micro-nutrients such a zinc, magnesium and copper, all of which are essential for crop growth.

Municipal wastewater treatment facilities separate the liquid and solid portions of wastewater. The solid portion undergoes biological treatment during which organic material is digested, or stabilized, by micro-organisms. Upon completion, biosolids must be analyzed for acceptability. This ensures that biosolids meet the quality standards, set by the Province of Ontario, and are suitable for land application.

Biosolids are a means to help municipalities reduce input, infrastructure and disposal costs, and to provide a cost effective way for farmers to meet the nutrient requirements for field crops.

For more information on the beneficial use of biosolids please follow the links below:

Or check out the following video:

All sewage biosolids must be stabilized through a MECP approved anaerobic or aerobic digestion process before being spread on agricultural land.

Digestion of the sludge provide stabilization reducing pathogen levels and breaking down organic matter into plant available nutrients.

Despite over 50 years of research which shows that, when conducted according to regulations, the land application of biosolids is safe, concerns remain over soil and groundwater contamination from trace elements, toxic chemicals and potentially harmful disease causing organisms (pathogens). To date, there have been no documented negative human cases where a biosolids program met all the provincial requirements. Finally, odors associated with the land application of biosolids are considered more of a nuisance than a health problem. Odours are often times the most objectionable aspect of biosolids use on neighbouring farms.

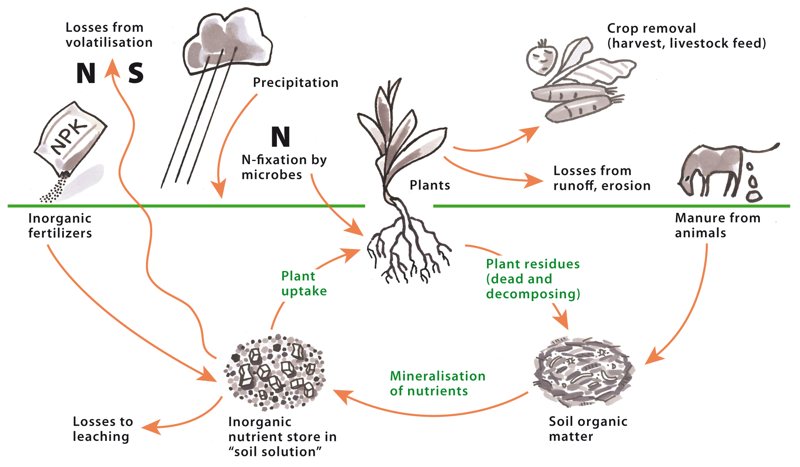

Despite over 50 years of research which shows that, when conducted according to regulations, the land application of biosolids is safe, concerns remain over soil and groundwater contamination from trace elements, toxic chemicals and potentially harmful disease causing organisms (pathogens). To date, there have been no documented negative human cases where a biosolids program met all the provincial requirements. Finally, odors associated with the land application of biosolids are considered more of a nuisance than a health problem. Odours are often times the most objectionable aspect of biosolids use on neighbouring farms.Using biosolids as a soil amendment closes the nutrient loop wherein harvested plants take nutrients from soil, humans obtain nutrients from the plants, and then we return nutrients to soil with biosolids. Biosolids are an endlessly renewable resource restoring carbon and nutrients to the land for the good of plants, and people.

Biosolids deliver a full suite of macronutrients and micronutrients, making them a superior source of plant food over synthetic fertilizers. Biosolids have a proven ability to improve soil structure thereby reducing runoff and erosion. Choosing to use biosolids as a soil amendment also reduces greenhouse gas emissions into the atmosphere.

Recycling biosolids onto agricultural land reduces the amount of material to go to landfill or incineration, but it also reduces the demand for commercial fertilizer required to grow a crop. Biosolids improve soil fertility, increase organic matter by enhancing soil structure and permeability, and reduce the potential for erosion.

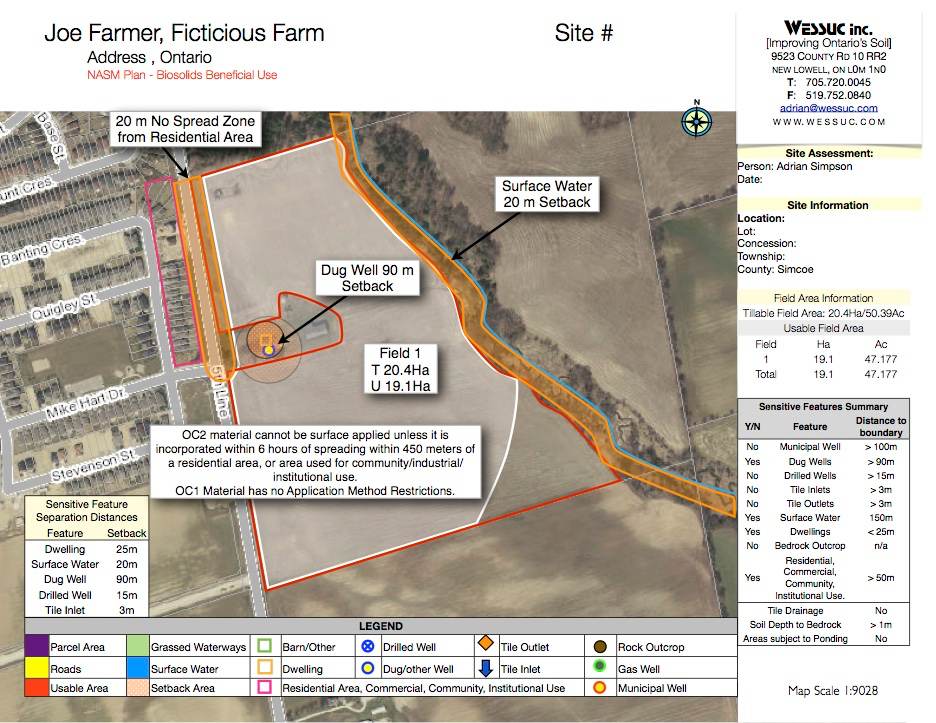

The short answer is no. Only farms that meet the criteria outlined in the Nutrient Management Act may receive biosolids. Criteria such as farming practices (crop rotation, nutrient application (manure, fertilizer), etc.), agronomic soil tests below 60ppm of phosphorous and above a pH of 6, slopes below 12% near surface water, municipal wells, residential wells, ground water and proximity to areas of commercial, community or institutional use must be accounted for in a field management plan. The Ontario Ministry of Agriculture, Food, and Agribusiness will review the plan and provide an approval before biosolids can be applied.

Additional unregulated features like municipal wellhead protection areas or other environmentally sensitive areas must also be taken into consideration during the assessment.

If you would like to use biosolids on your farm please contact us and we will evaluate your farm to determine it’s suitability and the application methods that are appropriate for your location.

The amount of biosolids that can be spread on a farm is governed by the Nutrient Management Act (NMA). Through extensive research, authorities have produced acceptable application limits for nitrogen, as well as 5 year application limits for phosphorus and heavy metals. All of these limits are outlined in the NMA. In general a farm site may receive biosolids to supply nutrients for that year’s crop. Setbacks from environmentally sensitive features such as wells, creeks, high slopes etc. also effect the amount of biosolids that a field may receive.

Since no two fields are exactly the same, specific characteristics of a field must be looked at to determine a plan that will benefit the farmer and protect the environment. These characteristics, or factors, consist of soil type, slope, intended crop, nutrient requirements to grow the crop, nutrients applied by the farmer (i.e. manure, fertilizer), and available nutrients within the soil. Following the plan will ensure nutrient applications do no exceed the crop requirements, which could cause negative environmental impacts.

Using these factors, it may be possible to have multiple biosolids applications over a 5 year period.

Biosolids cannot be applied unless an approved NASM plan (Non-Agricultural Source Material plan) has been obtained through the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA).

Once an approval is received, biosolids can be applied by licensed individuals from April 1st to November 30th, as long as the ground is not snow covered or frozen. The soil must be relatively dry and a crop is required to be established within one year of application. Generally, the spreading season occurs in the spring prior to planting, throughout the summer after the hay or sod has been harvested, and then in late summer through the fall after the fields (i.e. wheat, soybeans, etc) have been harvested. The Nutrient Management Act governs all field application requirements and outlines additional restrictions for each spreading season.

Yes, biosolids have been land applied in Ontario and Canada for well over 50 years with no documented health or environmental problems. However some counties have embraced it better than others. Australia, for example, has 81% of there treated sewage land applied as biosolids; Canada on the other hand, is currently using 33% of it’s sewage production as biosolids. However, the demand is growing as there is an increasing number of municipalities that see it as a cost effective and beneficial way to recycle their sewage.

Yes, biosolids have been land applied in Ontario and Canada for well over 50 years with no documented health or environmental problems. However some counties have embraced it better than others. Australia, for example, has 81% of there treated sewage land applied as biosolids; Canada on the other hand, is currently using 33% of it’s sewage production as biosolids. However, the demand is growing as there is an increasing number of municipalities that see it as a cost effective and beneficial way to recycle their sewage.Information on biosolids can be obtained throughout our website. If you have a specific question you cannot find an answer to please contact us at 1-866-493-7782 or email us.

For information on the legislation or best management practices check out the Ontario Ministry of Agriculture, Food, and Agribusiness or call their nutrient management hotline at 1-866-242-4460.

Land application of biosolids is considered a safe practice in Ontario when managed in accordance with the Nutrient Management Act (NMA), O.Reg 267/03. The NMA was developed by the Province of Ontario to provide for the management of materials containing nutrients in ways that will enhance protection of the natural environment and provide a sustainable future for agricultural operations and rural development. Excessive amounts of nutrients, which are present in biosolids, fertilizer and manure, can produce negative impacts on the environment. Despite over 50 years of research which show that, when conducted according to regulations, land application of biosolids is safe, concerns remain over soil and groundwater contamination from trace elements, toxic chemicals and potentially harmful disease causing organisms (pathogens). To date, there have been no documented negative human cases where a biosolids program met all the provincial requirements. The NMA provides specific requirements for nitrogen, phosphorus, metal and pathogen concentrations that must be met before biosolids can be land applied. Finally, odours associated with the land application of biosolids are considered more of a nuisance than a health problem. Odours are often times the most objectionable aspect of biosolids use on neighbouring farms.

Land application of biosolids is considered a safe practice in Ontario when managed in accordance with the Nutrient Management Act (NMA), O.Reg 267/03. The NMA was developed by the Province of Ontario to provide for the management of materials containing nutrients in ways that will enhance protection of the natural environment and provide a sustainable future for agricultural operations and rural development. Excessive amounts of nutrients, which are present in biosolids, fertilizer and manure, can produce negative impacts on the environment. Despite over 50 years of research which show that, when conducted according to regulations, land application of biosolids is safe, concerns remain over soil and groundwater contamination from trace elements, toxic chemicals and potentially harmful disease causing organisms (pathogens). To date, there have been no documented negative human cases where a biosolids program met all the provincial requirements. The NMA provides specific requirements for nitrogen, phosphorus, metal and pathogen concentrations that must be met before biosolids can be land applied. Finally, odours associated with the land application of biosolids are considered more of a nuisance than a health problem. Odours are often times the most objectionable aspect of biosolids use on neighbouring farms.

All restrictions are conservatively set to prevent toxicity or health impacts in plants, animals and humans.

The Nutrient Management Act provides minimum regulated standards to protect groundwater. These standards are in place to prevent nutrients that are present in biosolids from leaching into ground water table through infiltration. The NMA states that there must be a depth of at least 0.9 meters of dry soil when applying biosolids to prevent nutrients from leaching into groundwater.

The amount of biosolids applied to the soil is also restricted by soil type. This prevents biosolids from moving quickly in the soil. Soil types such as sand and loam have a high infiltration rate large soil particle sizes and drain very quickly. When applying biosolids to sand, application rates must be limited to ensure no seepage to ground water occurs. However, soil types like clay and clay loam have poor infiltration rates due to small particle sizes to which biosolids are more likely to be retained within the rooting zone of the field.

The NMA also provides restrictions when applying biosolids to areas with exposed bedrock. Bedrock that is too close to the soil surface can cause poor infiltration and pose a higher risk for ground water contamination. For this reason, there must be at least 0.9m of soil above bedrock.

Biosolids also contain unique properties which inhibit leaching to groundwater. These properties include charged particles, bacteria, and pathogens that bond to organic matter in the soil. When bacteria and pathogens bond to soil particles, they are less likely to enter ground water and can be broken down by soil microbes, sunlight and weather.

For more information on groundwater please visit the Ontario Ministry of Natural Resources page here.

Biosolids, like any fertilizer, binds to soil particles which may enter nearby streams and surface water during heavy rainfall events.

All nutrients that are applied to a field should follow Best Management Practices and/or regulation by establishing buffer zones to surface water. These nutrients include manure, commercial fertilizer, anaerobic digestion materials, old feedstocks, NASM and other agricultural source materials.

Regulations are in place to prevent water pollution by biosolids. Both BMP’s and NMA instruct applicators to maintain buffers along surface water areas like streams and municipal ditches.

The regulations enforce a minimum separation distance of 20 meters between the biosolids application area and surface water.

Slopes near surface water also restrict application rates. Application of biosolids is prohibited on slopes over 12 % which are located within 150 meters of surface water. This ensures that biosolids would not have direct access to surface water due to runoff.

Water pollution is also prevented by maintaining lower application rates on clay and clay loam soils. Clay soils usually have a low permeability which can present a higher risk of runoff which can greatly affect waterways. To prevent this from happening, lower application rates and methods can be used to allow biosolids to infiltrate more rapidly into the soil.

As well, biosolids cannot be applied to land that is snow covered or frozen. Snow covered and frozen ground can prevent biosolids from being incorporated or retained in the soil effectively. This may result in biosolids movement off of the field and into the waterway.

Application methods like direct injection, pre-application tillage, and immediate incorporation greatly reduce runoff potential.

Yes. Please don’t eat them. A major public health and environmental concern associated with land application of biosolids is the effect of pathogens on humans and animals. Like any organic waste (manure, food waste…), biosolids contain microorganisms that should not be ingested. Pathogens are disease causing organisms such as bacteria, parasites, and viruses.

The potential for exposure diminishes over time as environmental conditions such as heat, sunlight, desiccation, and other microorganisms destroy pathogens that may be present in biosolids. In order to be approved for land application, biosolids must be treated to reduce the number of pathogenic organisms. This treatment will reduce the level of bacteria and viruses by 95% and reduce parasitic content by 66%.

To minimize the potential risks during application, legislation requires a setback to be established between the application area and any wells or surface water that are located within specific distances. These setbacks are strictly enforced. A mandatory waiting period between biosolids application and cropping or pasturing acts as a safety precaution.

A common misconception is that the pathogens in biosolids are more harmful then the pathogens in animal manure. Biosolids have been spread for over 75 years with no documented evidence of causing harm to human health.

Certain toxic chemicals that do not volatilize or decompose during treatment may concentrate in biosolids. Therefore, the best environmental solution is prevention. The Municipal Act, 2001, gives municipalities the authority to enact sewer use bylaws to regulate what and how much is discharged into their sewer systems. Depending on the municipality, these bylaws may set limits on just a few basic parameters, such as temperature and pH, or they may set out rules for a long list of pollutants. In some cases they may require sewer users to think about changing manufacturing processes, reformulating products, or finding ways to capture and reuse wastes. In many cases, industries have found that pollution prevention projects tend to pay back in a short time.

Residues from chemicals have greatly declined over the past 40 years. Benzene, for example, was detected in 93% of biosolids samples in a survey conducted during the late 1970’s, but in only 3% of samples from the late 1980’s. Detection of persistent pesticides such as chlordane, dieldrin, heptachlor, and hexachlorobenzene were detected in 16% of the 1970’s samples, but none of the 1980’s samples. These declines are due to pretreatment, chemical bans and the phasing out of chemicals.

Yes, biosolids do smell. Some smell more than others, which is typically connected to the type of processing they have received. Most odours associated with the biosolids are reduced during the treatment process, but as the organic materials break down, odours are released. The method of application also has an effects on odour, injecting biosolids below the soil surface minimizes the potential for odours. In most cases, odours dissipate after a few days, similar to animal manure.

Yes, biosolids do smell. Some smell more than others, which is typically connected to the type of processing they have received. Most odours associated with the biosolids are reduced during the treatment process, but as the organic materials break down, odours are released. The method of application also has an effects on odour, injecting biosolids below the soil surface minimizes the potential for odours. In most cases, odours dissipate after a few days, similar to animal manure.Note: Biosolids are categorized as either OC1 or OC2.

Soil sampling is the process of collecting soil samples from various locations within a field or agricultural area to analyze the soil's physical and chemical properties. It is a vital part of effective nutrient management in crop production, providing an asseement of the essential nutrient levels including: phosphorus, potassium, organic matter, pH, zinc, manganese, sulfur, and magnesium. This helps determine the correct nutrient management program including fertilizer requirements for the best crop yield, while protecting the natural environment. Wessuc provides a variety of soil sampling services and recommendations to fit your agricultural needs.

Soil sampling is the process of collecting soil samples from various locations within a field or agricultural area to analyze the soil's physical and chemical properties. It is a vital part of effective nutrient management in crop production, providing an asseement of the essential nutrient levels including: phosphorus, potassium, organic matter, pH, zinc, manganese, sulfur, and magnesium. This helps determine the correct nutrient management program including fertilizer requirements for the best crop yield, while protecting the natural environment. Wessuc provides a variety of soil sampling services and recommendations to fit your agricultural needs.Heavy metals are regulated in the NMA.

Historically, industries disposed of their liquid wastes in to the sanitary sewer system, causing high metal concentrations in biosolids. Since the late 1970’s, sewer use by-laws have been established, as well as pretreatment requirements to reduce or remove heavy metals before they enter the sanitary sewer system. These by-laws have been very effective in decreasing heavy metals directed to wastewater treatment facilities.

Heavy metal mobility and availability to plants can increase under certain conditions; inorganic and organic components, to which metals are usually linked, are more easily dissolved in acidic soils, to minimize this, the NMA requires a minimum soil pH value of 6 or greater and requires testing of the 11 regulated metals in the soil and biosolids product prior to land application. The 11 regulated metals are Arsenic, Cadmium, Chromium, Cobalt, Copper, Lead, Mercury, Molybdenum, Nickel, Selenium and Zinc. The NMA provides a table outlining the maximum addition to soil and the maximum concentration in soil for each of these metals. Some metals, such as Copper, Molybdenum, Nickel, Selenium and Zinc are essential micronutrients for plant growth, but are only required in minute amounts.

Concentrations of regulated metals in biosolids are consistently well below regulation standards.

Tanker trucks are used to deliver liquid biosolids to fields. The tanker trucks that haul liquid biosolids generally hold 45 cubic meters (≈12,000 gallons). A field that is spread with an average application rate of 110 m3/ha would receive 2.5 truck loads per hectare. A 10 hectare (25 acre) field would receive an average of 25 truck loads during the application.

Tanker trucks are used to deliver liquid biosolids to fields. The tanker trucks that haul liquid biosolids generally hold 45 cubic meters (≈12,000 gallons). A field that is spread with an average application rate of 110 m3/ha would receive 2.5 truck loads per hectare. A 10 hectare (25 acre) field would receive an average of 25 truck loads during the application.

Truckers are required to follow all local county transportation requirements. Haulage routes are planned to avoid residential roads whenever possible. Also, land application typically occurs during regular working hours to minimize the potential inconvenience caused by the trucks.

Biosolids deliver a full suite of macronutrients and micronutrients, making it a superior source of plant food over synthetic fertilizers. Macronutrients include large amounts of nitrogen and phosphorus along with a small amount of potassium.

Biosolids deliver a full suite of macronutrients and micronutrients, making it a superior source of plant food over synthetic fertilizers. Macronutrients include large amounts of nitrogen and phosphorus along with a small amount of potassium. Plants, like all living things, require nutrients for growth. In nature, plants obtain nutrients from the soil. These nutrients are returned to the soil when the plant dies and decays. However, this natural cycle is interrupted when agricultural harvesting removes all or part of the plant from the land. Farmers must replace nutrients in their soil by applying a nutrient rich product such as a commercial fertilizer, manure, compost, or biosolids. The addition of nutrients to soil helps to maintain the soil health and fertility. Using biosolids as a nutrient source recycles nutrients that would otherwise be dumped in landfills or incinerated. For this reason, farmers apply NASM as nutrients for their crops and reduce the demand for commercial fertilizers. When applying NASM it is important to adjust fertilizer and animal manure rates to ensure only safe amount of nutrients are applied to the soil.

Plants, like all living things, require nutrients for growth. In nature, plants obtain nutrients from the soil. These nutrients are returned to the soil when the plant dies and decays. However, this natural cycle is interrupted when agricultural harvesting removes all or part of the plant from the land. Farmers must replace nutrients in their soil by applying a nutrient rich product such as a commercial fertilizer, manure, compost, or biosolids. The addition of nutrients to soil helps to maintain the soil health and fertility. Using biosolids as a nutrient source recycles nutrients that would otherwise be dumped in landfills or incinerated. For this reason, farmers apply NASM as nutrients for their crops and reduce the demand for commercial fertilizers. When applying NASM it is important to adjust fertilizer and animal manure rates to ensure only safe amount of nutrients are applied to the soil.Biosolids contain both organic and inorganic nitrogen. After biosolids application, the inorganic nitrogen is available immediately to crops. Organic nitrogen must be converted into inorganic nitrogen via nitrogen mineralization prior to being available to the crops.

During application of biosolids, volatilization (loss of nitrogen to the air) occurs, but with injection of biosolids, the loss is minimized; the remaining ammonia nitrogen is available to plants or converted to nitrate nitrogen.

The available nitrogen in both commercial fertilizer and biosolids could eventually find it’s way into the groundwater, which can cause a health risk to humans and animals if consumed. Strict NMA guidelines have been put in place to limit the amount of nitrogen that can be applied through biosolids. This limit will vary with crop type and application timing.

Phosphorus is essential to all vegetative life. It’s primary role is to store and transfer energy produced by photosynthesis for use in the growth and reproductive processes. Adequate phosphorus levels encourage positive effects like vigorous root and shoot growth and can promote early maturity. These effects often increase water use efficiency and potential grain yield.

Phosphorus is a main component in both commercial fertilizers and biosolids. Forty percent of the phosphorous in biosolids is released during the first year after application, the remainder is slowly released over time. Biosolids are most effective when applied to soils that are deficient in phosphorous. Soils are considered deficient when the soil has less than 60 mg/L of (sodium bicarbonate extractable) phosphorous.

Although excess levels of phosphorous are not toxic to plants, erosion of phosphorous laden soil can lead to surface water quality problems such as excessive algae and weed growth. Legislation in Ontario (Nutrient Management Act) does not permit application of biosolids where soil tests indicate the presence of more than 60 mg/L of sodium bicarbonate extractable phosphorous within the top 15 cm of soil.

Nitrogen, Phosphorus and Potassium are essential nutrients for plant growth. These nutrients are predominant in biosolids, but may vary depending on the treatment process, storage, and type of biosolids that are applied. Biosolids are treated in such a way that the nutrients will also fluctuate slightly from day-to-day so an average of sample analysis is used.

Only a portion of the nutrients applied are available within the first year. Below is a calculated average of what the benefits of biosolids may look like on a typical field within the first year of biosolids application:

| Nutrient | Units of Measurement | Total amount from biosolids application | Amount that is available first year | Typical Requirements for a crop of corn |

|---|---|---|---|---|

| Nitrogen (TKN,NH3, etc.) | kg/ha | 330 | 132 | 135 |

| lbs/ac | 295 | 118 | 121 | |

| Phosphorous | kg/ha | 140 | 129 | 75 |

| lbs/ac | 125 | 115 | 67 |

The Nutrient Management Act (NMA) governs the safe management of materials containing nutrients in ways that will enhance protection of the natural environment and provide a sustainable future for agricultural operations and rural development. The NMA was developed by the Province of Ontario in consultation with the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA), Ontario Ministry of the Environment, Conservation and Parks (MECP), Ontario Ministry of Health, the University of Guelph and the Ontario Federation of Agriculture.

The NMA is provided by OMAFA and all fields must be approved by OMAFA before biosolids can be land applied. OMAFA has also established guidelines for Best Management Practices (BMPs) for Nutrient Management and Application of Municipal Sewage Biosolids to Cropland. You can obtain a copy of the NMA and BMP’s online or at your local OMAFA office.

MECP is responsible for enforcement and compliance. They ensure that the regulation is followed during biosolids application through on-farm inspections.

Violators of the NMA can face severe consequences such as monetary fines or imprisonment.

The NMA came into effect in September 2003. The Nutrient Management Act (NMA) governs the safe management of materials containing nutrients in ways that will enhance protection of the natural environment and provide a sustainable future for agricultural operations and rural development. It was developed by the Province of Ontario in consultation with the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA), Ontario Ministry of the Environment, Conservation and Parks (MECP), Ontario Ministry of Health, the University of Guelph and the Ontario Federation of Agriculture.

In January 2011 the NMA was amended to include NASM (Non-Agricultural Source Material). NASM is any material that is not from an agricultural source and is capable of being land applied as a nutrient. This includes biosolids. The change to regulation and application process provide specific limitations for beneficial use. The biggest advantage to the change is that farms are approved by OMAFA instead of the MECP, which increases the chance that people knowledgeable about farming practices are approving the applications. Another key advantage from previous legal legislation is all nutrients applied must be taken into consideration for the next crop. For example, if biosolids supplied 75% of the nutrients required to grow a field crop then the farmer must ensure that he does not exceed the remaining 25%. This can provide a significant advantage to farmers through the ability to apply biosolids whenever the cropping practices allow (nutrient uptake and removal) which will greatly reduce the amount of commercial fertilizer required to grow their crops. Thus, reducing demand and input costs.

NASM is short for Non-Agricultural Source Material. NASM is any material that is not from an agricultural source and is capable of being land applied as a nutrient.

Not all materials can be classified as NASM. Materials must meet a stringent list provided under the Nutrient Management Act to be considered a nutrient, or a beneficial material for land. If a material cannot meet the minimum standards for NASM. It cannot be land applied and often times ends up in a landfill.

The requirements for beneficial use are:

The NMA lists 3 different categories of NASM. Each having their own list of sampling requirements and restrictions.

Category 1 - is unprocessed plant material (eg. Vegetable peels, vegetable washwater that contains food grade cleaners, etc.)

Category 2 - is processed plant material (eg. food waste, Bakery Waste)

Category 3 - Pulp and paper mill biosolids, sewage biosolids, animal based material (eg. meat processing plant waste, municipal biosolids)

Plant growth and the availability of most nutrients and micro-nutrients are affected by the pH of the soil.

For optimal intake of nutrients the soil PH should be between 6.5 & 7.0.

If levels are below 6.0, Ontario regulations prohibit the land application of biosolids. This is because some soil components, such as metals, are more available for plant uptake in acidic soils. Farmers are encouraged to apply neutralizing lime to raise the pH. If neutralizing lime has been applied, the soil may be re-tested, and if the pH is above 6.0, land application may take place.

No, biosolids must be applied and hauled by individuals who hold specific licenses to do so.

Individuals who are applying biosolids must hold a current nutrient application technician license. This ensurers the operator has been trained and passed an examination to properly handle nutrients. The Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA) provides course training and examinations required to obtain a license. All biosolids haulers in Ontario must also obtain approval by the Ministry of the Environment, Conservation and Parks. These approvals are issued as Environmental Compliance Approvals (ECA). During transportation of biosolids the approval number must be displayed on the unit.

The Ministry of the Environment, Conservation and Parks inspects and enforces the NASM plans for all sites across Ontario.

Injection is the placement of nutrients below the surface of the soil of the land.

The Nutrient Management Act (NMA) outlines acceptable biosolids application rates based on specific field conditions but does not require biosolids to be injected. The only unacceptable form of application is irrigation. There are many cases where farming practices do not allow for injection (hay, cover crops, no-tillage practices, etc.) and some farmers prefer to use there own tillage equipment and will allow us to surface apply then they will incorporate after biosolids are applied.

Injection can provide exceptional benefits such as reduced odour emissions, increased nutrient capture (less likely to volatilize into the atmosphere or erode), ability to place the nutrients directly into the root zone/seed bed, and provides tillage. Each one of these benefits greatly enhances environmental protection and increases potential yield.

Wessuc is fully equipped to accommodate all approved methods of application.

Wet well - the area at the pumping station where wastewater collects to allow pumping. It is literally a well of wastewater.

Dry well - the area of the pumping station where the pumps and other equipment are located.

Digesters, like other tanks, need to be cleaned on a regular basis to ensure optimal performance.

Despite advancements in mixing equipment technology, all digesters sooner or later build up a bottom deposit of sand grit and heavy solids of all descriptions. Additionally, most digesters form a scum blanket on the top of the digester. Both the build up on the bottom of the tank and the scum blanket reduce the digesters effective treatment capacity and lead to short circuiting or reduced efficiency.

A digester is a tank designed for the biological treatment of organic matter.

The tank is designed to provide control of pertinent operation and environmental variables. The operation and environmenal variables are controlled so that treatment can occur at accelerated rates. Although there are various methods of digestion, all have a common goal of stabilizing the sludges they receive.

Most tanks need to be cleaned for one of two reasons:

Tank cleaning is becoming increasingly important for optimal wastewater and water treatment plant performance.

Most waste water treatment plants have a regular schedule for their tank cleaning based on historical records and present tank efficiency monitoring.

However often tanks are cleaned for emergency repairs or for inspection purposes. Small tanks such as septic tanks will need to be cleaned on a regular basis depending on the loading they receive. Each case is unique to the function of the tank and other components of the plant or process.

A confined space is a space in which, or from which, access or egress is restricted and in which, because of its construction, location, contents or the work activity therein, a hazardous gas, vapour, dust, fume or oxygen-deficient atmosphere may occur.

As a rule of thumb any area which was not designed for regular human occupancy should be considered a confined space. Examples include tanks, silos, hoppers, bins, dust collectors, vats, pipes, sewers, pumping stations, digesters, liquid manure spreaders, chemical storage tanks, and wells.

Prior to entering a confined space, all safety equipment must be inspected for defects, and setup appropriately to allow fast response in case of emergency.

The atmosphere must be tested prior to entry and all electrical or mechanical devices locked out, or completely disabled. A safety person is required to watch the entrant at all times, in case of emergency. Often times during tank clean outs, for example, the gas levels in the tank will change drastically as the material is stirred up. Continuous gas monitoring is essential.

It is important to perform routine pipe inspections to ensure that sewage systems are functioning properly.

CCTV is a preventative measure that keeps you confident in the integrity of your pipes and informs you in the event of cracks, intrusions, offset joint, and other pipe damages so that the proper measures can be taken to prevent serious damage and overflow.

Maps of the infrastructure are ideal for helping our teams know what areas may require attention.

For municipalities, it is important to know the type of access, upstream or downstream manhole, and if there is a GIS system (Geographic Information System Map).

Our crews at Wessuc have found some pretty bizarre things during our pipe inspections. There have been raccoon sightings, some icicles, a garbage blockage, and even a storm drain that was filled with dirt.

Inspecting your pipes fills our day with surprises.

It is important to flush pipes to clear out and properly dispose of any debris that has built up. Debris is harmful because it hinders or prevents pipe flow which can damage sewer systems or lead to overflow. Therefore, flushing is a method to restore pipe flow, maintaining pipe integrity, and allowing for pipe inspection to occur.

Wessuc’s flusher has a powerful recycling system that reclaims water to clean sewers in an environmentally friendly manner while saving your municipalities money.

Reaming involves adding an attachment, such as a chain, to a specific nozzle on a flusher truck to smash or chop whatever obstructions are within the pipe as the hose is pulled back through it.

Cutting is more precise, using a robot to focus on a specific problem or intrusion in the pipe.

Experience the difference experience can make. Whether it’s cleaning, inspecting, moving, or reusing material. We get it done.

Let's do it